Megawatt Charging Multidirectional Microgrids

Feasibility study into depot-based charging of Electric Heavy Goods Vehicles by integrated design and operation

The UK government’s ten-point plan for a green industrial revolution, published in November 2020[1], includes the ambition to accelerate the shift to zero emission vehicles.

Subsequently, in November 2021, the UK government committed to phase out new, non-zero emission heavy goods vehicles up to 26 tonnes by 2035, and new, non-zero emission HGVs in all weight classes by 2040[2].

The ICCT confirm that the leading zero emission HGV technology is electrification[3], but there are significant challenges in transitioning to an electric HGV fleet, not least of which are the complexity of charging infrastructure and optimisation of the recharging schedule.

Business Challenge

As energy costs continue rising, it is imperative to determine the most cost-effective charging infrastructure and the most efficient operations, which will provide the lowest cost energy consumption.

Commercial operators of HGV fleets face significant challenge to reconcile all costs, which must be considered within the business case for HGV electrification.

Solution

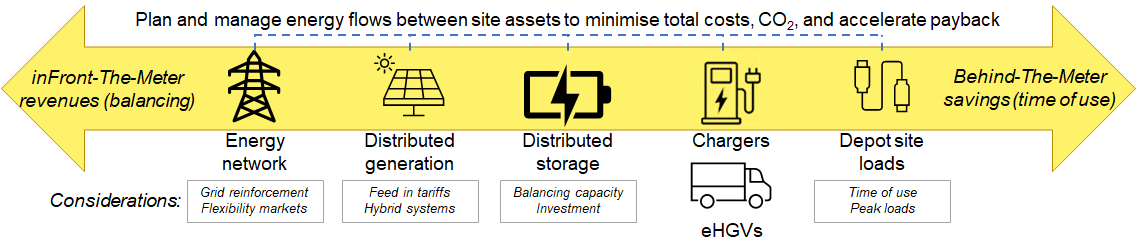

While electricity costs are around half the equivalent diesel fuel costs, efficient operation through intelligent charging and responses to system stress events in the electricity distribution network can achieve further energy cost savings, up to half as much again.

And intelligent charging offers further potential to manage power flows between vehicles, depots or other buildings (such as warehouses), and the electricity distribution network, achieving greater savings.

Scope and benefits

This feasibility study evaluates the design and integration of electric HGV charging equipment and buildings, comprising a local “microgrid”, including energy storage to buffer high power flows.

This approach unlocks the benefits of energy demand and supply management. Commercial operators of HGV fleets will benefit from:

Lower Total Cost of Ownership and faster payback on capital investments,

An understanding of the energy costs for different scheduling decisions,

Revenue opportunities from using electric HGVs as energy assets,

Lowest carbon footprint and verified sustainable operations for customers,

Resilience to energy network supply issues.

Project Objectives

System simulation of a site microgrid for performance and power management optimisation,

A techno-economic model to maximise investment return.

Project Outcomes

Accurate, tailored cost models for a range of electric HGV and charging infrastructure options,

Cost benefit analyses demonstrating potential savings to our commercial partners and customers.

Inputs definition

Electric Vehicle Supply Equipment study

Commercial case development

Microgrid sizing study

Simulation model development

Energy storage models

Energy storage study

Help for Fleet Operators

If you are a commercial operator of HGV fleets you are welcome to contact the project team for further information on this project, or to receive guidance on transitioning to electric vehicles and charging infrastructure. The team may also be able to support your Total Cost of Ownership calculations.

As a starting point, please provide your depot postcode and fleet size at depot.

This is a UK-based project, but the project partners welcome international enquiries, to help understand the impact of the project outcomes in an international context.

Project Funding

Innovate UK project #10036648: This project is part of the V2X Innovation Programme, funded by BEIS and delivered by Innovate UK. V2X is part of the Flexibility Innovation Programme, funded from the Net Zero Innovation Portfolio.

For more information, please contact: info@syselek.com